High-speed production: The equipment adopts efficient roll forming technology, which can greatly improve production efficiency. The specific production speed depends on the model and configuration of the equipment, but it can usually achieve a higher production speed to meet the needs of large-scale production.

Precision forming: The dimensional accuracy and shape consistency of the metal keel are ensured through high-precision molds and rolling processes. The formed metal keel has excellent mechanical properties and surface quality, meeting the standards and requirements of the construction industry. Multi-model

production: The equipment supports the production of various models of metal keels, including C-type, U-type and W-type. Special shapes of metal keels can also be customized according to customer needs to meet the needs of specific application scenarios.

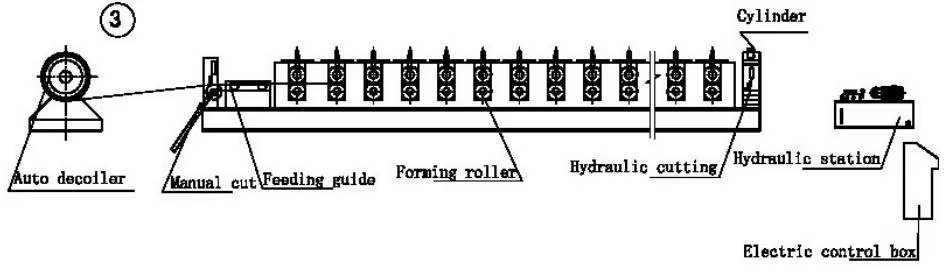

Automated control: Equipped with advanced automated control systems to achieve intelligent operation of the equipment. Production parameters such as production speed, molding pressure, etc. can be set by programming to optimize production results.

Easy to operate and maintain: The equipment is easy to operate and understand, and is equipped with detailed operating manuals and training instructions. The equipment is easy to maintain, easy to disassemble and clean, reducing maintenance costs and time.