|

العنصر

|

القيمة

|

|

طاقة

|

6كيلووات

|

|

المكونات الأساسية

|

PLC، المحرك، المحمل، علبة التروس، المحرك، الترس، وعاء الضغط

|

|

مادة العمود

|

فولاذ عالي الجودة 45#

|

|

المواد الخام

|

الزنك

|

|

نظام التحكم

|

PLC

|

|

سمك المادة

|

0.3-0.6 ملم

|

|

مواد شفرة القطع

|

فولاذ عالي الجودة Cr 12

|

|

الضرب

|

لكمة هيدروليكية

|

|

السرعة

|

20-25م/دقيقة

|

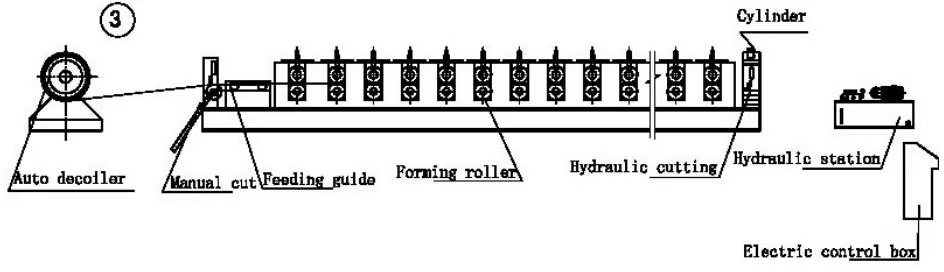

مخطط سير العملية