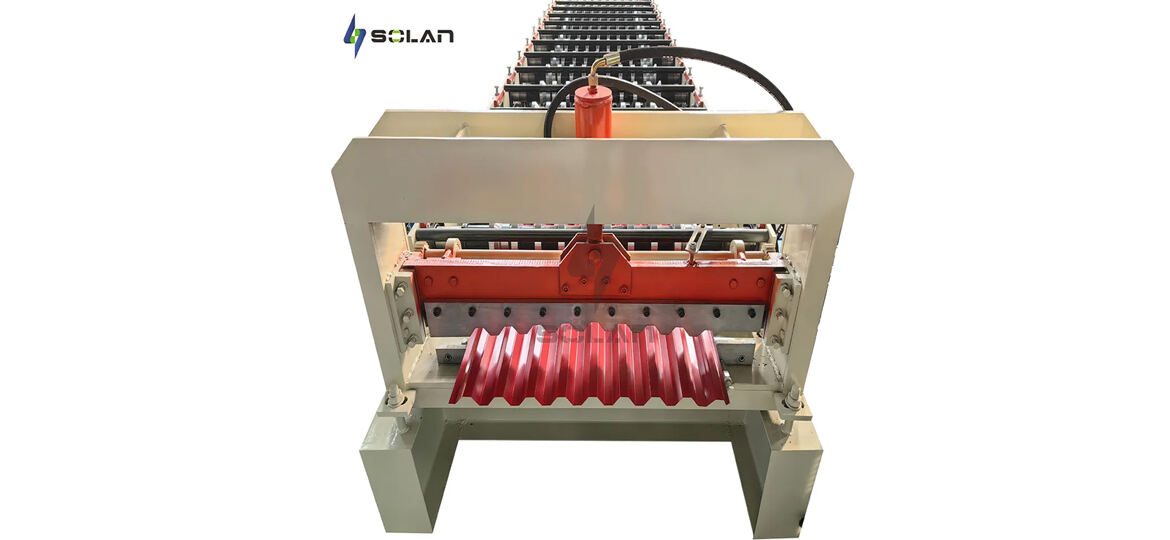

Wraz z szerokim zastosowaniem urządzeń do formowania na zimno, prasy do płytek stały się niezbędne w produkcji paneli dachowych, paneli ściennych i innych wyrobów metalowych. Aby zapewnić efektywne działanie urządzeń i bezpieczeństwo personelu, niezbędne jest przestrzeganie specyfikacji eksploatacyjnych. Poniżej przedstawiono normy i zalecenia branżowe dotyczące pracy z prasą do płytek.

1. Przygotowanie przed uruchomieniem

· ·kontrola sprzętu:

Upewnij się, że wszystkie części prasy płytkowej są nienaruszone, zwłaszcza czy rolki, ostrza i układ przesyłowy są w normalnym stanie.

· ·Połączenie zasilania:

Sprawdź, czy przewód zasilania jest prawidłowo podłączony i czy napięcie spełnia wymagania urządzenia w celu uniknięcia zwarcia lub obciążenia.

· ·Utrzymanie smaru:

Regularnie sprawdzać i dodawać smarownik zgodnie z instrukcją obsługi urządzenia, aby zapewnić sprawną pracę walców i części przekładni.

2. Wykorzystanie Środki ostrożności podczas pracy

· ·Stabilne karmienie:

W trakcie karmienia metalową cewkę należy utrzymać na płaskim poziomie, aby uniknąć zmarszczek lub przesunięcia, co wpłynie na efekt formowania.

· ·Wystrzymanie przeciążenia:

Kontrola prędkości produkcji i grubości materiału zgodnie ze specyfikacjami konstrukcyjnymi urządzenia w celu uniknięcia przekroczenia zakresu obciążenia maszyny.

· ·Monitorowanie w czasie rzeczywistym:

Podczas pracy urządzenia operator musi obserwować stan urządzenia w czasie rzeczywistym, jeśli stwierdzone zostaną nieprawidłowości (takie jak nieprawidłowy hałas, wibracje), maszyna powinna zostać natychmiast zatrzymana do kontroli.

3. Wykorzystanie Wymagania operatora

· ·Kształcenie zawodowe:

Operatorzy muszą przejść systematyczne szkolenie w zakresie obsługi urządzeń oraz opanować podstawowe etapy działania oraz metody leczenia awaryjnego.

· ·Nosić sprzęt ochronny:

W czasie pracy należy nosić rękawiczki ochronne, okulary i inne wyposażenie, aby zapobiec obrażeniom z powodu cięć i złamania metalu.

·Zakaz nieautoryzowanej eksploatacji:

Niewykwalifikowanym osobom jest surowo zabronione obsługiwanie urządzenia bez upoważnienia lub bezpośrednie dotykanie obracających się części podczas pracy urządzenia.

4. Wykorzystanie Wsparcie po zatrzymaniu maszyny

· ·Oczyszcz maszyny:

Po zakończeniu produkcji należy w odpowiednim czasie oczyścić pozostałe szczątki i kurz na sprzęcie, aby utrzymać czystość sprzętu.

· ·Regularne kontrole:

Wykonywanie kompleksowej kontroli sprzętu raz w miesiącu, w tym układu elektrycznego, komponentów przesyłowych i zużycia narzędzi.

· ·Zarządzanie rejestrami:

Ustalenie rejestrów użytkowania i konserwacji urządzeń w celu ułatwienia śledzenia następczych napraw i konserwacji.

Trend rozwoju przemysłu: bardziej inteligentne i zautomatyzowane

Wraz z postępem Przemysłu 4.0 nowoczesne prasy płytkowe stopniowo rozwijają się w kierunku inteligencji i automatyzacji. Wiele zaawansowanych urządzeń zostało wyposażonych w układ sterowania ekranem dotykowym i system diagnostyki usterek, co znacznie zmniejsza trudności w ręcznej obsłudze i poprawia wydajność produkcji.

Naukowa i standaryzowana obsługa jest kluczem do efektywnej pracy i przedłużenia żywotności maszyny do prasowania płytek. Zawsze jesteśmy zaangażowani w dostarczanie klientom wysokiej jakości sprzętu i profesjonalnego wsparcia technicznego, aby pomóc każdemu użytkownikowi w osiągnięciu sytuacji dobrego wyniku w zakresie bezpieczeństwa i wydajności w produkcji. Jeśli chcesz dowiedzieć się więcej o umiejętnościach w zakresie obsługi i konserwacji maszyny do tłoczenia płytek, zapraszamy do odwiedzenia naszej strony internetowej lub skontaktowania się z naszym zespołem technicznym!